The truth will out: we are here to unveil the full scale of the government’s complicity in genocide and to hold it to account for the monstrous bloodshed in Palestine, writes JEREMY CORBYN

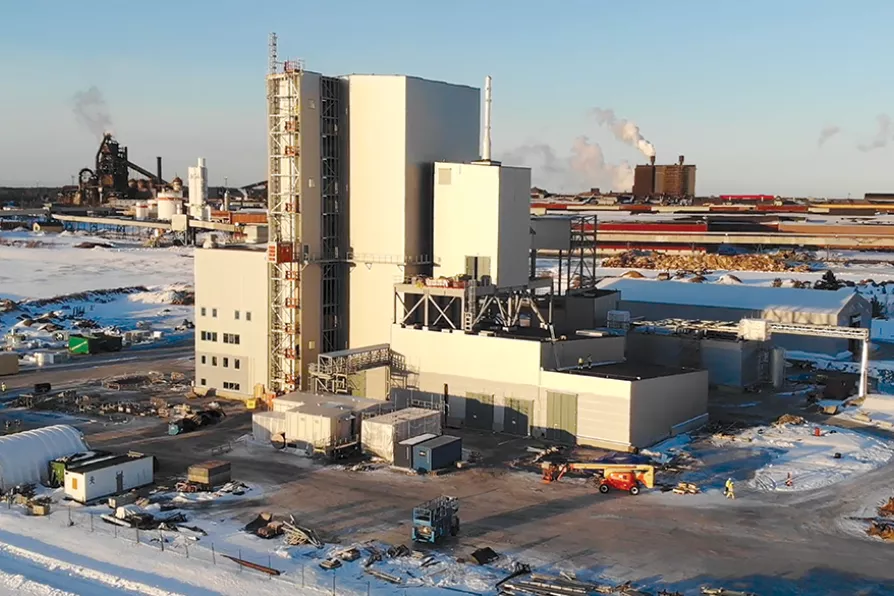

GROUNDBREAKING INNOVATION: Hybrits testing facility in Lulea, Sweden, February 2020

[AndersFrick/CC]

GROUNDBREAKING INNOVATION: Hybrits testing facility in Lulea, Sweden, February 2020

[AndersFrick/CC] IN EARLY December, Michael Gove approved the foundation of the first new deep coal mine in Britain for more than 30 years. Rishi Sunak’s government is enthusiastic about British coal — but why?

The Conservatives are historically associated with closing down coal mines, not opening them.

Coal is an extreme pollutant, reducing air quality and releasing greenhouse gases.

What’s behind the stubborn gender gap in Stem disciplines ask ROX MIDDLETON, LIAM SHAW and MIRIAM GAUNTLETT in their column Science and Society

While politicians condemned fascist bombing of Spanish civilians in 1937, they ignored identical RAF tactics across the colonies. Today’s aerial warfare continues this pattern of applying different moral standards based on geography and race, write ROX MIDDLETON, LIAM SHAW and MIRIAM GAUNTLETT

The distinction between domestic and military drones is more theoretical than practical, write ROX MIDDLETON, LIAM SHAW and MIRIAM GAUNTLETT

Nature's self-reconstruction is both intriguing and beneficial and as such merits human protection, write ROX MIDDLETON, LIAM SHAW and MIRIAM GAUNTLETT